Pasta maker

The best pasta machines for every need: which to choose?

The market offers a wide range of pasta machines, each designed for a specific stage of the production process. These machines, created to simplify and ensure consistent production, are the beating heart of artisanal pasta shops and food industries worldwide. From mixers to presses, from sheeters to formers, each machine plays a precise role in creating the perfect pasta: one that combines taste, texture, and authenticity.

Today, thanks to increasingly versatile and professional solutions, anyone can transform semolina and water into a high-quality product, with the same care as an artisan workshop but with the efficiency of modern technology.

However, choosing the right equipment can seem complex for those entering this world for the first time. The options are many, and each machine meets different production needs: those who want to start with small quantities will find an excellent starting point in compact and multifunctional machines, while those aiming for larger production will need to look towards modular systems capable of growing with the business. Understanding your own needs - from the desired type of pasta to the daily quantity to be produced - is the first step to making a conscious choice that is crucial for building your ideal workshop, optimizing work, and achieving high-quality results.

Pasta machines can be divided into the following main categories:

- Hand extruders: manual pasta extruders work thanks to a simple yet effective screw mechanism, operated by a crank handle. The dough, previously prepared and placed in the extruder's cylinder, is pushed by a piston that advances slowly with the rotation of the handle. This constant pressure forces the dough through a bronze or other material die, located at the end of the cylinder. The shape of the die determines the type of pasta obtained, such as spaghetti, maccheroni, tagliatelle, and many other shapes. As the pasta emerges, it is cut manually to the desired length. Modern electric extruders evolve this concept, replacing manual force with a motor. In these models, the motor drives the piston automatically, making the extrusion process faster, continuous, and less strenuous, ideal for larger productions or for those seeking greater convenience.

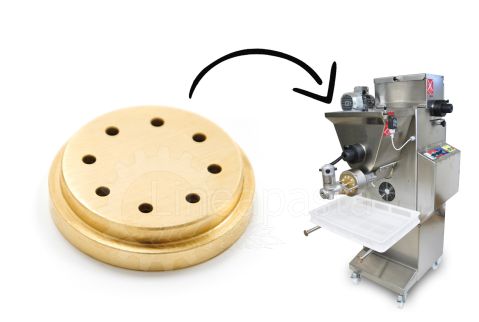

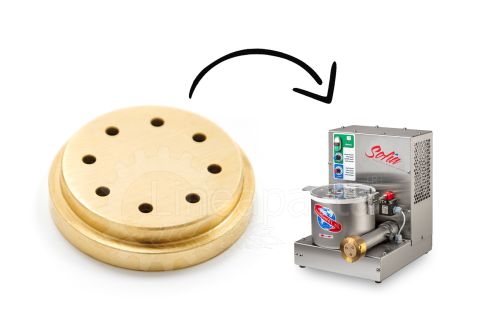

- Presses: fresh pasta presses are the cornerstone of artisanal and professional production, offering solutions for every need, from small restaurants to more structured workshops. Made primarily of stainless steel to ensure durability and ease of cleaning, these machines are designed to mix and extrude any type of semolina and flour, allowing for the creation of short pasta, long pasta, and pasta sheets with a single tool. The most advanced models are equipped with a water-cooling system that allows for continuous production without overheating the dough and a fan for pre-drying the product. The inclusion of an electronic pasta cutter, with adjustable speed, automates and speeds up the production of short pasta shapes.

An indispensable complement to the press is the die, the tool that gives the pasta its shape. Made of brass with bronze inserts, these dies give the pasta that characteristic rough and porous surface, ideal for holding any type of sauce. Different are the dies with teflon or PTFE inserts, which instead give the pasta a smoother and shinier appearance. The versatility of the presses is amplified by the vast range of available dies, which allow for the creation of countless shapes: from spaghetti to penne, from caserecce to special shapes, up to adjustable-thickness sheets, the base for lasagna and cannelloni. The combination of a high-performance press and the choice of the right die is the secret to obtaining superior quality fresh pasta, true to tradition. - Sheeters: sheeters are essential pieces of equipment in both domestic and professional settings, indispensable for anyone wishing to produce fresh pasta sheets, but also for pastry and baking applications. Their functional core consists of a pair of rollers or laminating cylinders typically made of stainless steel to give the dough a smooth and homogeneous appearance, or of wood to give a more "artisanal" look to the sheet, much more similar to the result obtained with a wooden rolling pin. Through an adjustment mechanism, usually a numbered knob, it is possible to change the distance between the rollers with extreme precision. This allows the operator to pass the dough through the cylinders multiple times, gradually reducing its thickness until the desired one is reached, from a few millimeters to fractions of a millimeter. The mechanical and controlled process not only eliminates the fatigue and irregularity of manual rolling with a rolling pin but also improves the structure of the dough, making it more compact, elastic, and homogeneous. The result is a perfectly smooth and uniform-thickness sheet, the ideal base for creating tagliatelle, lasagna, and ravioli. From manual crank-operated models, perfect for home use, to professional electric ones, more robust and equipped with powerful motors for large production volumes, the sheeter represents a tool that combines tradition and technology to ensure a superior quality final result.

- Gnocchi machines: gnocchi machines are specialized machines that automate and perfect the gnocchi production process. Designed to work with doughs of different consistencies, from the classic potato-based one to those with special flours or ricotta, these machines replicate manual processing in a mechanical and fast way. The operation begins by placing the dough in a special loading hopper. From here, an extrusion system gently pushes the dough, forming continuous strands. An adjustable and synchronized cutting unit then sections the strands into small pieces of uniform size. The most important phase is the forming: the machine passes each piece over a device that gives it its characteristic hollow shape and ridged surface, essential for holding the sauce. It is also possible to make gnocchi without ridges or as small "chicche," depending on how the machine is set up. To ensure that the finished product does not stick, gnocchi machines are almost always equipped with an automatic duster that distributes a light layer of flour. Made entirely of stainless steel to ensure hygiene and ease of cleaning, these machines offer unparalleled advantages in terms of production speed and, above all, consistency of the final product, ensuring all gnocchi are the same in weight and shape, and therefore cook perfectly evenly.

- Ravioli machines: ravioli machines are high-precision machines, indispensable for pasta factories and workshops specializing in the production of filled pasta. They are specifically designed to automate the creation of filled pasta such as ravioli, tortelli, and agnolotti, ensuring an artisanal quality product on an industrial scale. Their operation, in the case of double-sheet ravioli machines, is based on the synchronized coupling of two pasta sheets, previously prepared by a sheeter. These are continuously fed into the machines, where the bottom sheet passes over a forming unit. A filling dispensing system, adjustable in quantity for perfect control of the pasta-to-filling ratio, deposits a dollop of filling (based on meat, ricotta, vegetables, or fish) at regular intervals on the bottom sheet. Immediately after, the top sheet is placed over it to cover everything. At this point, a pair of cylinders or a pressure mold, depending on the model, seals the two sheets together, hermetically sealing the filling inside while simultaneously cutting the raviolo into its final shape.

The most important and versatile feature of professional ravioli machines is the ability to use interchangeable molds, which allow for a very easy variation of the shape and size of the product: square, round, half-moon, fish-shaped, or other special shapes.

These machines ensure not only very high production speed but, above all, extraordinary quality consistency. Each raviolo is perfectly sealed, with the same amount of filling and a flawless shape, thus ensuring uniform cooking and preventing the annoying leakage of the filling, a result that requires great skill and time if done manually.

The secret is in the die: how bronze and teflon change pasta

If the dough is the soul of the pasta, the die is what gives it its identity. It is through this component that the mixture of semolina and water comes to life, taking the desired shape: spaghetti, penne, fusilli, or rigatoni. But the die doesn't just determine the shape - it also decisively affects the texture, appearance, and even the pasta's ability to hold sauce.

Dies are mainly distinguished by the material they are made of: bronze or teflon (PTFE). Both versions have specific characteristics and advantages, designed to meet different production needs and achieve different results.

The tradition of the bronze die

Bronze die extrusion is the traditional method, prized for its ability to create pasta with a rough and porous surface. This slower, more artisanal process offers significant advantages in terms of taste and quality.

Characteristics of bronze-die pasta:

- Porous surface: the friction between the dough and the bronze die creates micro-roughness on the pasta's surface. This feature is fundamental because it allows it to better hold any type of sauce, ensuring a perfect union between the pasta and the sauce.

- Better nutritional properties: this type of processing, combined with slow drying, better preserves the nutritional qualities of durum wheat semolina, maintaining a higher content of protein, minerals, and vitamins.

- Quality of semolina: bronze die extrusion requires the use of superior quality semolina, capable of withstanding the mechanical stress of the process without breaking down.

The efficiency of the teflon die

Teflon dies, on the other hand, represent the more modern and productive choice. The pasta that comes out has a smooth and shiny surface, with a uniform and professional appearance. This finish is ideal for large-scale production, where the focus is on speed, consistent yield, and a perfect visual appearance.

Characteristics of teflon-die pasta:

- Smooth and shiny surface: teflon, being a non-stick material, allows the dough to slide through more easily. The result is a pasta with a smooth surface and a more intense, brilliant yellow color.

- Less wear on the die: teflon reduces friction during extrusion, allowing for smoother production and limiting die wear.

- Lower capacity to hold sauce: the smooth surface makes the pasta less suitable for absorbing sauces, a detail that makes it preferable for shapes intended for ready meals, short cooking times, or industrial production.

- Faster and more economical production: the process is faster and teflon dies require less maintenance, factors that contribute to a lower final product price.

In conclusion, the choice between bronze-die and teflon-die pasta depends on personal preference and the importance given to quality and the taste experience. If you are looking for a pasta that can enhance the sauce to the fullest and appreciate a heartier texture, bronze-die extrusion is undoubtedly the best choice. If, however, you prioritize quick cooking and a lower cost, Teflon-die pasta can be a valid alternative.

The charm of fresh pasta: a journey between tradition and innovation

Fresh pasta is one of the pillars of Italian cuisine, a culinary art with roots that go back centuries. From the simple homemade pasta sheet made with a rolling pin to the professional machines that now populate workshops and kitchens around the world, the journey of pasta is a perfect blend of tradition and innovation.

The history of fresh pasta is as fascinating as it is complex, and its origin has long been a subject of debate. Although popular myth attributes the introduction of pasta from China to Marco Polo, historical evidence suggests that its evolution occurred independently in different Mediterranean cultures. The art of mixing flour and water to create a dough is a custom that dates back to ancient civilizations, but it is in the Middle Ages that pasta, as we know it today, begins to take shape.

A crucial role in the spread of pasta, especially dried pasta, was played by the Sicilians who, during the Arab domination, learned and perfected the drying technique. However, the history of fresh egg pasta, the heart of the culinary tradition we celebrate today, is closely linked to specific regions of northern and central Italy. The first written evidence of a "sfoglia" (pasta sheet) prepared with flour and eggs is found in documents and cookbooks from the 14th century, particularly in the noble courts of Emilia-Romagna, Veneto, and Lombardy.

In these areas, where chicken farming was common, the egg became a fundamental ingredient, capable of making the dough richer, more elastic, and flavorful. Places like Bologna, Ferrara, and Mantua established themselves as nerve centers for the production of fresh filled pasta, such as tortellini, tortelli, and cappelletti, giving life to a tradition that is still a source of pride and regional identity today.

From artisan shops to the machines of the 20th century

The industrialization of pasta is a relatively recent phenomenon. For centuries, production remained an artisanal art, a skill passed down from mother to daughter, using simple tools like the rolling pin and a cutting board. The first real innovations arrived with the industrial revolution.

The first pasta machines, often manually operated, were designed to lighten the workload in kitchens and small pasta shops. The first extruders and presses of the 19th century, operated by a crank, allowed for the production of short and long pasta shapes more uniformly and quickly than by hand. These tools, though rudimentary, marked a turning point.

With the advent of electricity, machines evolved rapidly, making the process even more efficient. The concept of the mechanical mixer was born, capable of mixing large quantities of ingredients, and electric sheeters, which guaranteed a perfect and constant thickness of the pasta sheet, unthinkable with just a rolling pin. This technological progress has democratized the production of fresh pasta, making it accessible not only to professionals but also to enthusiasts who wish to replicate the authenticity of a homemade dish.

Rediscovering the heart of tradition: the pleasure of homemade pasta

Choosing to buy a small pasta machine for your home is not just about getting a new appliance; it's an invitation to slow down, to rediscover the value of genuine food, and to turn every meal into a special occasion.

Modern machines are compact, intuitive, and easy to clean, fitting perfectly into any kitchen, even the smallest, without requiring professional chef skills. In just a few minutes, that dough transforms before your eyes: it becomes a thin, silky sheet with a sheeter, ready for lasagna or cannelloni, or it takes the shape of perfect tagliatelle. If you choose a small press instead, the fun multiplies: by changing a simple bronze die, you can make macaroni, fusilli, or bigoli, bringing a different shape to the table every day.

The greatest advantage of homemade production is absolute control over quality. You can buy the freshest eggs from a nearby farmer, select organic or stone-ground flours from local mills, or even experiment with special doughs, adding a touch of spinach, tomato, or squid ink. The result will be a pasta with an authentic flavor and an unparalleled texture, porous and capable of capturing the sauce like no industrial dry pasta ever could.

Having a pasta machine at home transforms food preparation into a moment of sharing. It becomes an activity to do with children, who will have fun watching the pasta take shape, or a way to impress friends at dinner, offering them a dish that is not only delicious but also tells a story of passion and care.

Ultimately, bringing a pasta machine into your home is a small investment with a huge return in terms of taste, health, and happiness. It means reclaiming an ancient knowledge, celebrating the richness of our land, and, above all, giving yourself and the people you love the greatest luxury: the unmistakable taste of things made with love.

How to enhance your restaurant with a fresh pasta workshop

In the current restaurant landscape, where authenticity and the quality of raw materials are increasingly decisive, choosing to produce fresh pasta directly in your own establishment is one of the most effective strategic decisions to stand out. Introducing a pasta machine doesn't just mean adding a piece of equipment to the kitchen; it means embracing a philosophy that communicates passion, tradition, and a deep connection to Italian culinary excellence. Here's how to take this step to turn it into a guaranteed success.

Before making a purchase, it is essential to evaluate your specific needs. The choice of the right machine depends on three key factors:

- Production volume: how many covers do you serve on average? A small restaurant with 30-40 covers will have different needs than one with 100. Evaluating the machine's production capacity (expressed in kg/h) is essential to ensure it can support the required pace without creating bottlenecks during service.

-

Type of pasta: what shapes do you want to offer? If the menu will focus on long egg pasta like tagliatelle, pappardelle, or lasagna, a professional sheeter is the starting point. If you want to explore bronze-extruded shapes (macaroni, fusilli, caserecce), you will need a press with the corresponding dies. Many modern machines combine both functions, offering unparalleled versatility.

-

Space and utilities: carefully assess the available space in the kitchen. There are compact countertop models, ideal for small spaces, and larger, more structured machines for true workshops. Also, check the electrical power requirements with the help of an electrician.

Once the equipment is chosen, integrating it into the kitchen's workflow is the next step.

-

Dedicate time to train one or more members of the kitchen brigade. Using the machine is often intuitive, but the real skill lies in perfecting the doughs and managing routine maintenance, such as cleaning at the end of a production shift, which is crucial for ensuring durability and hygiene.

-

The quality of the pasta will directly depend on the ingredients. Highlighting your local territory is the key to success; this choice will not only improve the product but will also become a powerful story to tell customers.

-

Dedicate a section of the menu to "our homemade fresh pasta." Start with a few classic shapes and then expand the offer. You can offer "shapes of the day" based on the seasonality of ingredients, communicating dynamism and creativity to customers.

In conclusion, integrating a fresh pasta machine is much more than a simple technical upgrade: it's a statement of your culinary identity. It's a return to the origins that elevates the perception of the establishment, builds customer loyalty, and opens up infinite creative possibilities, further rooting the restaurant in the excellence of gastronomic tradition.

Tips for optimal use and secrets for a perfect pasta

Purchasing a machine is only the first step. To achieve exceptional results, it is essential to follow a few tips:

- Choose the right flour: durum wheat semolina differs from soft wheat flour both in its more pronounced grain size and its characteristic amber-yellow color, a color that is also reflected in the products made with it. By further milling the semolina, you get re-milled semolina. This latter product is distinguished by the characteristic amber-yellow color of semolina but with a less pronounced grain size than the original material. Re-milled semolina is mainly used for bread-making and pasta. "00" flour, on the other hand, is produced from the milling of soft wheat and is usually used in addition to re-milled semolina for the production of pasta sheets, to give them more elasticity (generally in proportions of 50%). The suffix "00" indicates the highest degree of refinement (sifting).

- Dough moisture: the dough should be firm but not dry or sticky. It can be made to your liking with just water or by also adding eggs. The adjective "fresh" indicates a moisture level of around 30%.

- Machine cleaning: after each use, it is crucial to carefully clean the machine following the manufacturer's instructions. Pasta left in the machine dries and crusts, making subsequent use difficult.

Lineapasta answers: frequently asked questions

What are the basic ingredients to use with fresh pasta machines?

Fresh pasta is made from a few essential ingredients: re-milled semolina flour, eggs and/or water.

Re-milled durum wheat semolina gives the dough a coarse consistency, while the addition of '00' flour (in a 50/50 proportion) makes it more elastic, an ideal characteristic for preparing pasta sheets (sfoglia). Eggs add color and flavour, but can be substituted with water to obtain a lighter pasta. When preparing pasta sheets, it is advisable to omit the egg white, which tends to dry out the dough.

How does the pasta machine work? Do I need to use an already prepared dough?

The operation varies depending on the type of machine.

For presses, the ingredients are poured directly into the mixing vat (dry ingredients first, then liquid ones gradually) and the machine handles both the kneading and the extrusion phases.

For sheeters/rollers, a distinction must be made between models equipped with a mixing vat - which follow the same procedure as the presses - and models equipped only with laminating rollers. For the latter, the dough must be prepared separately, by hand or with a spiral mixer, and roughly flattened before being passed through the rollers.

What happens if the proportion of ingredients is incorrect?

The key to perfect pasta is always the correct consistency of the dough: neither too soft nor too dry. A correct dough is crumbly, with a texture similar to small "coffee beans." A practical method to check the right consistency is to squeeze a small amount in your fist: if, when you open your hand, the dough remains compact without leaving residue, it is ready for extrusion.

How to solve the problem of irregular edges in pasta shapes?

The presence of irregular edges is often due to a die that has not yet reached the optimal temperature. Dies ensure the best results when they reach approximately 40°C. A cold die tends to produce shapes with non-uniform and aesthetically unappealing profiles. To avoid this, it is advisable to heat the die by submerging it in hot water before use.

The dough created with your recipe is very different from the one I make at home, why?

Pasta machines require a specific dough consistency, different from the traditional one prepared by hand. Homemade recipes, such as the one that calls for 100 grams of flour for every egg, produce a mixture that is too wet. This tends to stick to the machine's mechanical components and can compromise correct functioning or cause damage during extrusion. It is therefore essential to check that the dough is of the right consistency before proceeding with the extrusion phase.

Are there formats that are more difficult to make?

Some pasta shapes are more complex to process, requiring particular attention, especially in the initial phases of using a pasta machine. Among these, fusilli and all shapes that need to rotate on themselves are a typical example. In these cases, the choice of flour is crucial: it is necessary to use a specific pasta flour with a high strength value (W), to ensure the shape maintains the correct curvature during extrusion.

How to clean and store a pasta machine?

The most important cleaning is the one performed after use, whether it is a press or a sheeter. It is very important to try to clean the machine while the residues are still fresh, as once they dry, it will be much more difficult to clean them, especially in the case of the dies.

For presses, with the machine turned off and unplugged from the power, remove the parts in contact with the dough and wash them without using detergents or soaps; use a damp cloth to clean the inside of the mixing bowl, ensuring all residues are removed.

DO NOT immerse the machine in water, DO NOT use abrasive sponges, and DO NOT use knives or other metal objects to remove the dough. Some models have a removable vat that can be washed in the dishwasher, but be sure you have the correct model before doing this.

For sheeters/rollers, with the machine always unplugged, clean all parts in contact with the pasta with a damp cloth.

Italiano

Italiano Français

Français Español

Español

AUD

AUD  BRL

BRL  CAD

CAD  CHF

CHF  CNY

CNY  GBP

GBP  INR

INR  JPY

JPY  KRW

KRW  RUB

RUB  THB

THB  USD

USD