Pasta hand extruders (Torchi)

What they are and what they're used for

A "torchio" is essentially a device that pushes dough (usually flour + water or flour + eggs + water) through a die (a perforated disk) to obtain the desired pasta shape. Essentially, the press (or extruder) produces the pasta already in the desired shape. The simplest and oldest versions are manual, and have evolved over time into more elaborate motorized versions, although the original manual press remains the same.

A Brief History

For centuries, pasta was made almost exclusively by hand, using a slow, artisanal process. Traces (though not exactly presses as we know them today) of wooden and bronze machines that used the principle of the die can be found as early as the 19th century.

For example, in the United States, in 1906, a certain Angelo Vitantonio obtained a patent for a hand-cranked machine for homemade pasta. With the Industrial Revolution and the advent of electricity, pasta machines evolved rapidly: home-use machines became more accessible, while industrial ones became more powerful and automated.

How they are composed

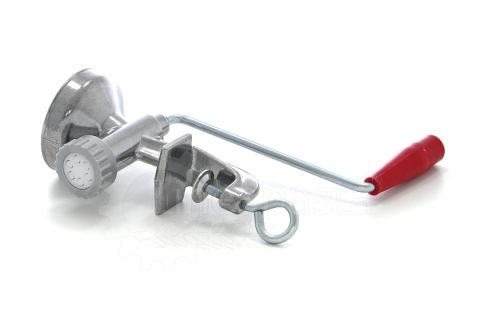

A "torchio" is made up of several components that can be divided as follows:

- Main structure: essentially the machine body, into which the previously prepared dough is inserted.

- Push mechanism: inside the main structure of the press, a endless screw (or auger) passes, connected to a crank located at the top of the press. By turning this crank, the screw rotates and simultaneously pushes the dough towards the lower part of the press, where the die is located.

- Die: this is the part that "shapes" the pasta, that is, where the dough passes through and takes its final shape. The die material (bronze or teflon) also influences the final texture of the pasta.

- Ring nut: this is the ring at the base of the press that holds the die in place. In some models, the ring nut is omitted because the die slides directly into the machine body from the top.

Pros and cons - manual and electric versions

Pros of the manual model:

- It is often cheaper, simpler to use, and does not require a motor or complex setup.

- Ideal if you are making fresh pasta for yourself or a few guests, without producing large quantities.

Cons of the manual model:

- Requires more physical effort (cranking, pushing, control).

- The pace is slower, less suitable if you need to produce a large quantity or in a short time.

- Sometimes, curled or tubular shapes are more difficult to achieve with just the crank.

Pros of the electric model:

- It greatly speeds up the process, reduces effort, and allows for more complex shapes and larger quantities.

Cons of the electric model:

- They cost more, take up more space, require electricity, and require more maintenance.

- In some cases, the heated dough or the automatic mechanism can slightly affect the texture of the pasta.

- Multiple systems = more components to clean/maintain.

Which one to choose

If it's just a hobby, and you want to enjoy making fresh pasta every now and then, and you're not interested in producing large quantities, a manual model is perfect: compact, more economical, and gives that "artisanal" feel.

If, on the other hand, you want to produce larger quantities (for example, for a large dinner with friends), the electric version offers a significant leap in quality.

Another factor: space and budget. A more powerful electric model requires more space, a larger budget, and also a minimum of maintenance and attention.

In the end, it's a matter of balancing: how much you want to produce, what you want to achieve, and how much you're willing to invest in effort and cost.

Italiano

Italiano Français

Français Español

Español

AUD

AUD  BRL

BRL  CAD

CAD  CHF

CHF  CNY

CNY  GBP

GBP  INR

INR  JPY

JPY  KRW

KRW  RUB

RUB  THB

THB  USD

USD