Pasta dies

Dies: the heart of perfect pasta

Dies are fundamental elements in pasta production, and their history is rooted in an artisanal context that later evolved into an industrial one. The term "trafila" appears in some Neapolitan collections as early as the 17th century, referring to the perforated plate through which the dough was pushed to obtain the desired shape.

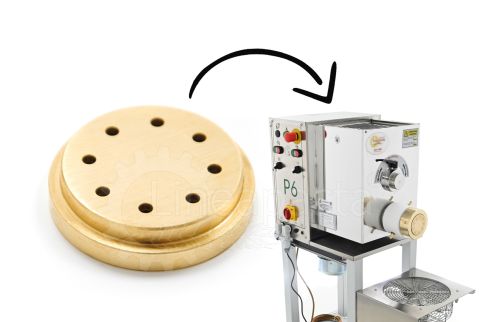

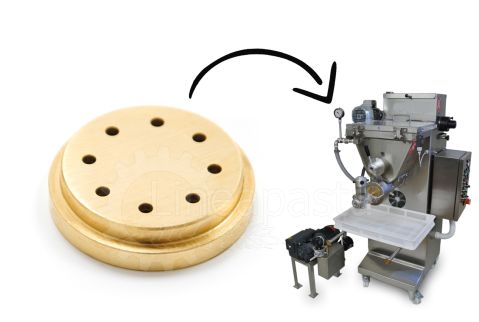

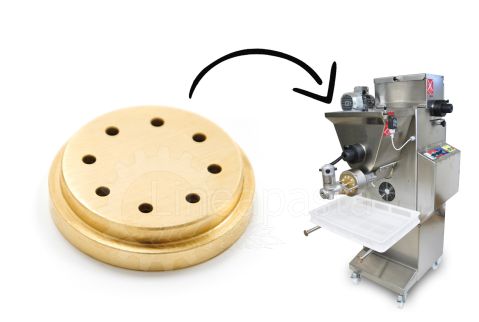

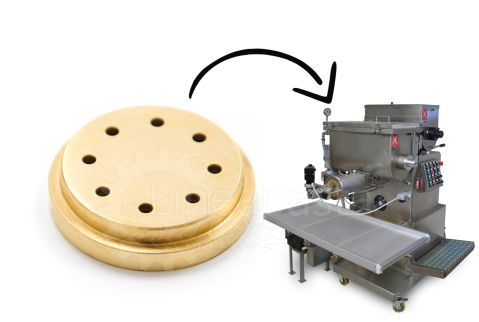

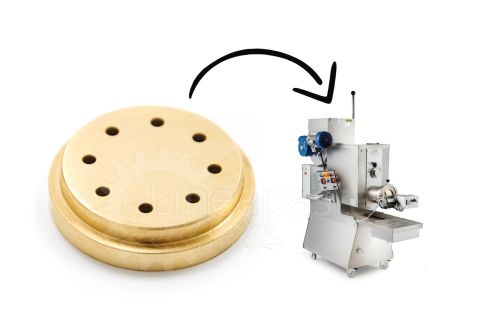

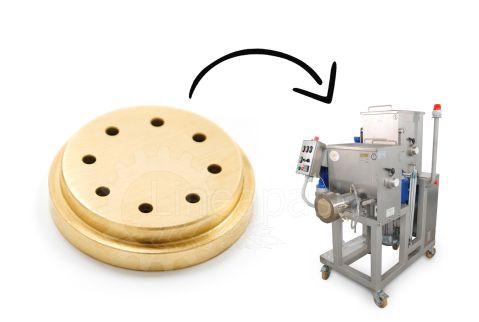

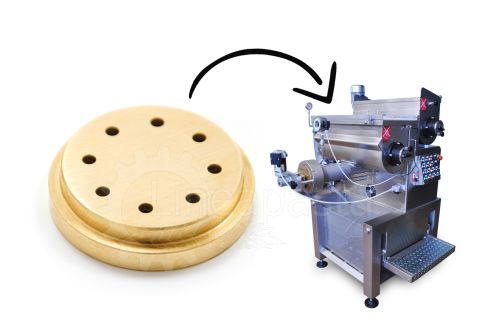

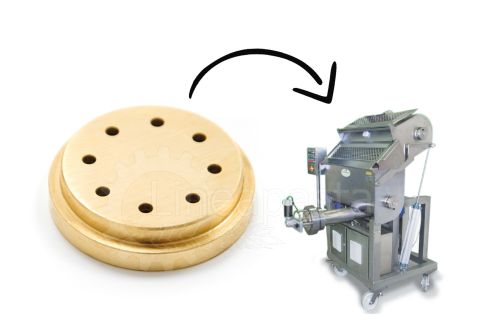

Technically, the die consists of a perforated metal plate or disk, through which the dough is pushed under pressure by the endless screw of the pasta machine. This can be operated manually (as in manual presses "torchi") or electrically. As the dough passes through the holes, it takes on the desired shape (spaghetti, penne, fusilli, and so on). In more recent versions, dies can be equipped with inserts that can be replaced once worn, maintaining the main structure of the die itself and allowing for easier maintenance.

As for materials, traditionally brass is used for the base and bronze or teflon for the inserts, each with distinct characteristics. The die with bronze inserts creates a pasta surface and profile characterized by a matte color and a rough, porous texture, which helps retain sauces and condiments. Furthermore, this type of die generally requires higher-quality semolina and slower, lower-temperature drying, both of which contribute to a richer organoleptic profile. The die with teflon inserts, on the other hand, produces a smoother, less porous pasta surface and a brighter color. This makes it suitable for more industrial production, where speed and yield are more important than the roughness of the final product. However, this smoother surface retains less sauce, and in some cases, nutritional quality may be slightly lower due to drying at higher temperatures and generally lower-quality semolina.

The inserts act as interchangeable components within the die: the main structure (disc or plate) remains fixed, while the inserts - the shaped parts that form the holes specific to the pasta shape - are replaced when worn or damaged. This solution extends the die's lifespan, reduces maintenance costs, and allows for the production of different shapes simply by changing the insert. In advanced industrial or artisanal settings, this means greater flexibility and long-term savings.

Cleaning and maintenance of the dies is essential after each production cycle: immediately after use, the dies should be immersed in water and left until their next use, making sure to change the water frequently. This prevents residues from drying out and will be easily extruded during the next production run. A water floss or an air compressor can be used to better clear the smaller holes. Oxidation or discoloration is perfectly normal when using this method of preservation.

Dies with teflon inserts, however, must be cleaned extremely delicately to avoid scratching the coating. In both cases, it's helpful to periodically inspect the die's flatness, the lock on the machine, and the proper connection between the die and the machine body to ensure uniform dough extrusion.

In summary: brass dies with bronze or teflon inserts are a key component in pasta machines. The choice of material profoundly impacts the final product, the required maintenance, and production costs. Bronze dies are preferred when tradition, quality, and a surface that holds the sauce are key; teflon dies are preferable when production demands speed, efficiency, and low cost.

Italiano

Italiano Français

Français Español

Español

AUD

AUD  BRL

BRL  CAD

CAD  CHF

CHF  CNY

CNY  GBP

GBP  INR

INR  JPY

JPY  KRW

KRW  RUB

RUB  THB

THB  USD

USD