Important: this object is no longer available because already sold or not for sale anymore. We invite you to visit our website to find any similar equipment.

Spaghetti Production Line 1500 kg/h

Price:

Not available We deliver worldwide

- Condition: New

- Guarantee: 12 months warranty

Description

Automatic long pasta line (Spaghetti)

SPAGHETTI PRODUCTION UNIT

Pasta dough is produced with water and semolina and this mixture poured into the dough boat. Then, each of Spaghetti is directed into die eyes on the vertical head. In here, the pasta dough takes Spaghetti shape and it is sent to extrusion unit to start drying steps.

TECHNICAL SPECIFICATION

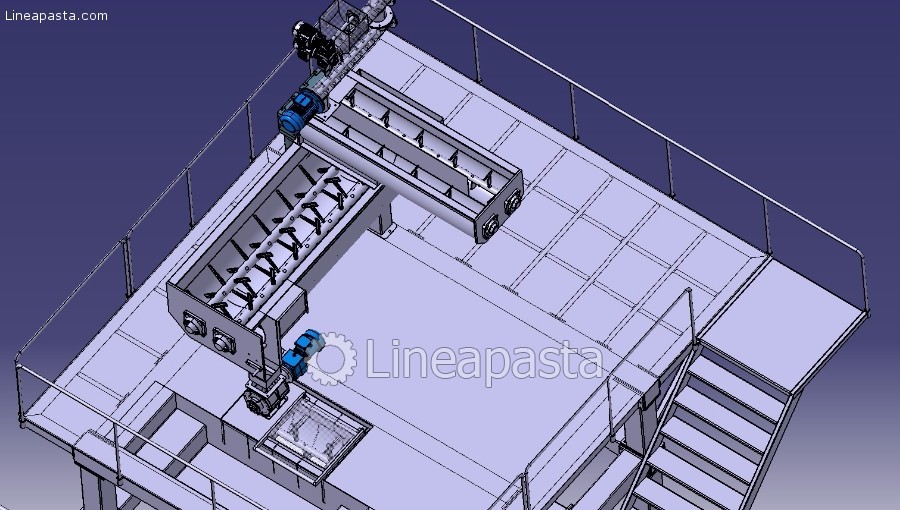

- Flour feeding unit

- Flour dosing with screw feeder

- Water dosing unit

- New model stainless steel Centrifugal Pre-mixer

- Stainless steel double mixer

- 3-cup capsuling

- Linear rectangular dies

- Heat unit

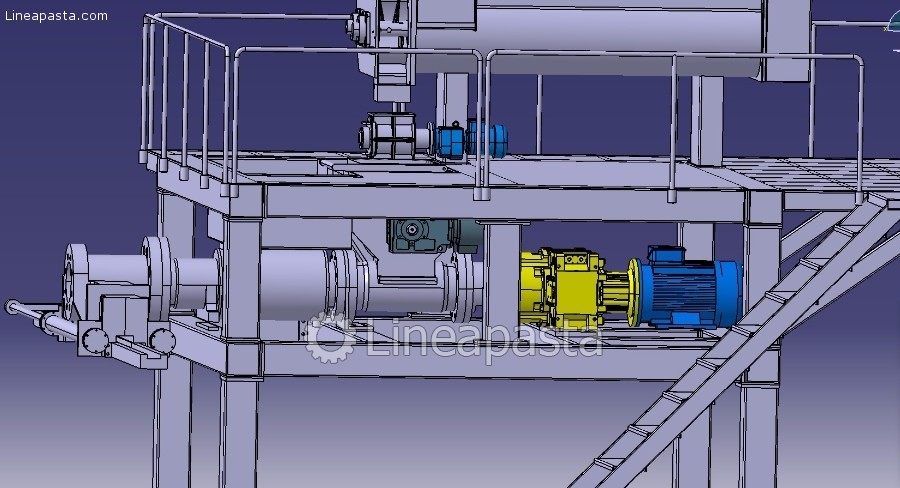

- Speed control reduction gears

- Double rectangular die

- Cylindrical press with diameter

- Vacuum mixer

THE SPREADER UNIT

The Spaghetti pasta get shape on die (mould), then Spaghetti is sent spreader unit. Spaghetti is hanged to aluminium sticks in here to send to dryer unit. The Spaghetti length controlled automatically on the sticks with automation system. Later the sticks are sent "zone-1" to start drying passenger. Zone-1 is first unit in zones.

SPAGHETTI PRE-DRYER ZONE-1

Zone-1 made one tunnel and one stage for designing Spaghetti pre-drying. The surface isolation provided polyester panels. These panels have completely opening system. All of this part skeleton made stainless chrome.

SPAGHETTI DRYER UNIT ZONE-2

Zone-2 made one tunnel and three stage for designing Spaghetti drying. The surface isolation provided polyester panels. These panels have completely opening system. All of this part skeleton made stainless chrome.

SPAGHETTI DRYER UNIT ZONE-3

Zone-3 made one tunnel and three stage for designing Spaghetti drying. In this unit Spaghetti pasta needs steam. This needing provided "system on/off option" automatically with automation system. The surface isolation provided polyester panels. These panels have completely opening system. All of this part skeleton made stainless chrome.

SPAGHETTI DRYER UNIT ZONE-4

Zone-4 made one tunnel and nine stage for designing Spaghetti drying. In this unit Spaghetti pasta needs steam. This needing controlled automatically with "system on/off option" on the automation system. The drying process finish in this part. The surface isolation provided polyester panels. These panels have completely opening system. All of this part skeleton made stainless chrome.

SPAGHETTI COOLER UNIT ZONE-5

Zone-5 made one tunnel and two stage for designing Spaghetti cooling. The surface isolation provided polyester panels. These panels have completely opening system. All of this part skeleton made stainless chrome.

SPAGHETTI COOLER UNIT ZONE-6

Zone-6 made one tunnel and two stage for designing Spaghetti cooling, then dryer unit. The surface isolation provided polyester panels. These panels have completely opening system. All of this part skeleton made stainless chrome.

THE STRIPPER UNIT

Spaghetti pasta complete pre-drying, main drying, cooling processing then come stripper unit to gain final length. This unit have high regulation circular knives. These knives have opposite rotation. The feeding bant transporter made rubber. Its structure is notch to carry Spaghetti from feeding bant transporter to cutter discs.

THERMAL HEAT CONTROL CENTER

All of temperature provided from thermal heat control center. We prepare sub-structure of line according to user preference. (Natural gas, Fuel Oil, Coil, Electricity).

Read more

Enter the delivery address to calculate the shipping costs and proceed with the purchase

Spaghetti Production Line 1500 kg/h

The product has been added to the cart

Italy

Italy

Germany

Germany

Ukraine

Ukraine

USA

USA

France

France

Singapore

Singapore

Canada

Canada

Australia

Australia

Czech Republic

Czech Republic

Estonia

Estonia